Choosing the best coolant for your metalworking processes can be challenging. The wrong choice might lead to inefficient machining, increased tool wear, and higher costs.

At Grind Lap, our expertise in metalworking solutions provides valuable insights into different types of coolants. We help you understand the nuances of each type and guide you in selecting the most effective coolant for your needs.

This guide will cover everything you need to know about metalworking fluids—emulsified oil, semi-synthetic, and synthetic coolants. Learn how each type affects performance, longevity, and cost, ensuring you make an informed decision for your machining processes.

Metalworking Fluids

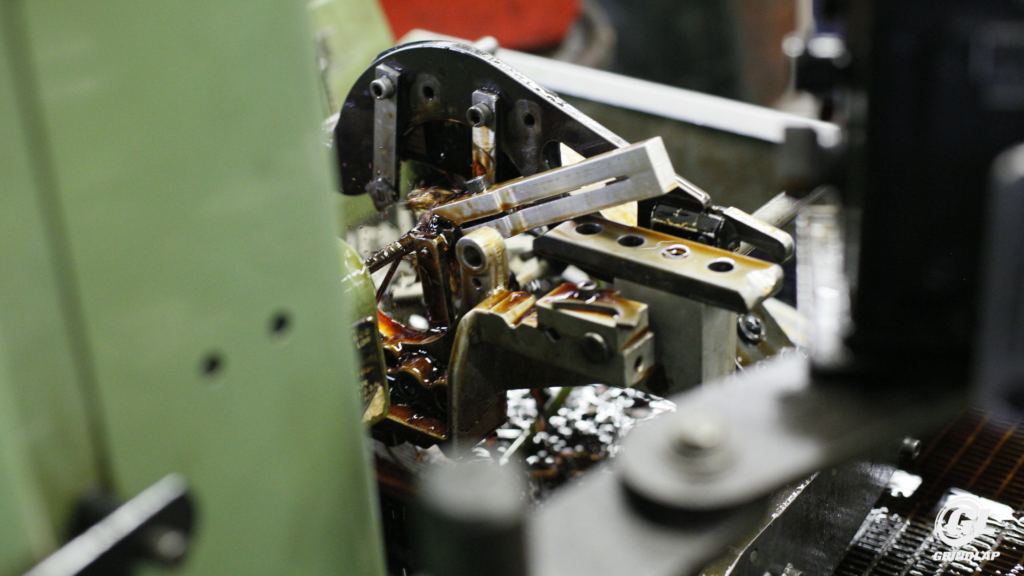

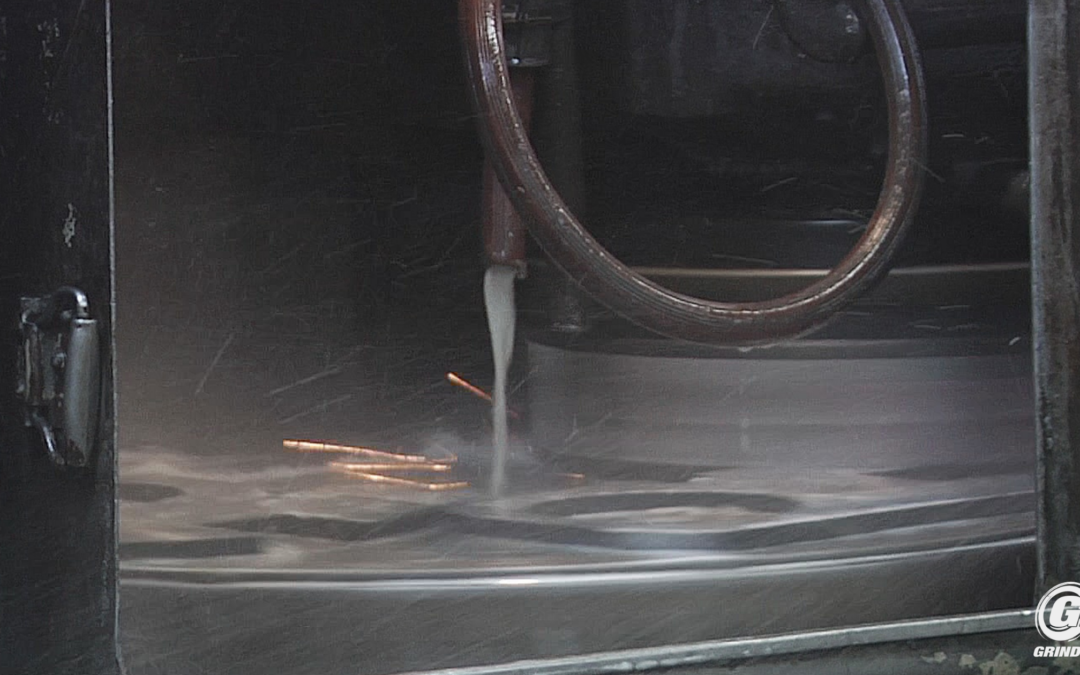

Metalworking coolants are used in various machining and manufacturing processes to improve machining efficiency and protect the metal from heat damage. The main functions of metalworking coolants are to:

- Cool Down: Reduce friction and heat generation during machining.

- Lubricate: Minimize wear and tear on the metal surface.

- Provide Corrosion Protection: Guard against rust and corrosion.

- Flush Debris: Remove chips and debris from the cutting area.

Types of Metalworking Coolants

- Emulsified Oil

- Description: Also known as soluble oil, this is a mixture of oil and water-based emulsifiers. It forms a stable solution when mixed with water.

- Applications: Suitable for light to moderate machining applications.

- Benefits: Provides good lubrication and corrosion protection.

- Semi-Synthetic Coolants

- Description: A blend of mineral oil, synthetic oil, and water-based emulsifiers.

- Applications: Offers better cooling and lubrication performance, suitable for moderate to heavy machining applications.

- Benefits: Improved corrosion protection, can extend tool life.

- Synthetic Coolants

- Description: Fully synthetic and free of mineral oil or emulsifiers.

- Applications: Ideal for heavy-duty machining applications.

- Benefits: Superior cooling and lubrication performance, excellent corrosion protection, longer lifespan than emulsified oil or semi-synthetic coolants.

Key Differences

- Cooling and Lubrication Performance: Synthetic coolants offer superior performance, followed by semi-synthetic and emulsified oil.

- Lifespan: Synthetic coolants generally have a longer lifespan.

- Cost: Synthetic coolants tend to be more expensive than emulsified oil and semi-synthetic coolants.

Conclusion

Selecting the appropriate metalworking coolant is crucial for optimizing machining efficiency and ensuring quality results. Emulsified oil is ideal for light to moderate tasks, semi-synthetic coolants are best for moderate to heavy applications, and synthetic coolants offer superior performance for heavy-duty machining. By understanding the differences and benefits of each type, you can make an informed choice that balances performance, cost, and longevity for your specific needs.

Recent Comments