Are you looking for efficient methods to achieve precise surface finishes and dimensional accuracy on your parts? Understanding the synergies between Blanchard grinding and flat lapping can significantly enhance your manufacturing capabilities.

Whether you’re dealing with geometric imperfections or striving for impeccable flatness, combining these precision machining processes offers a strategic advantage in optimizing your production outcomes.

At Grind Lap, we specialize in integrating advanced machining techniques to deliver superior surface finishes and dimensional accuracy. With expertise spanning across industries such as aerospace, automotive, and medical devices, we’ll be covering the benefits of combining Blanchard grinding and flat lapping in manufacturing operations.

Blanchard grinding and flat lapping are precision machining processes renowned for their ability to achieve precise surface finishes and sizes on various parts. Utilizing both methods in conjunction within the manufacturing process offers several strategic advantages.

In this guide, we’ll explore the strategic advantages of leveraging both methods in tandem. Discover how this combined approach enhances material removal efficiency, corrects geometric imperfections, and achieves unparalleled surface finish quality. By the end, you’ll gain actionable insights into optimizing your machining processes for enhanced productivity and superior part quality.

Blanchard Grinding: Efficient Material Removal

Blanchard grinding employs a vertical rotary grinding machine equipped with a spinning grinding wheel. This process swiftly removes material from the surface of a flat part, ensuring a flat and uniform finish. It excels in handling parts requiring significant material removal efficiently.

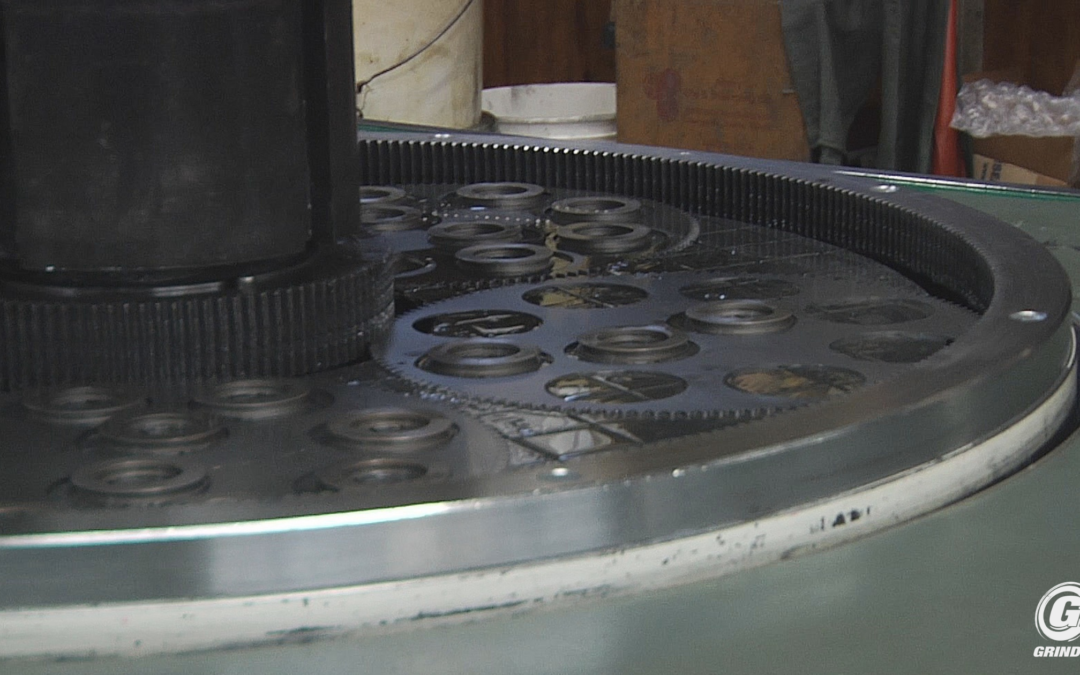

Flat Lapping: Precise Surface Finishing

Flat lapping utilizes abrasive particles to create a precise flat surface finish on parts. The process involves rubbing the part against a rotating flat surface covered with abrasive slurry. It achieves exceptional flatness and surface quality, making it ideal for parts demanding high precision.

The Advantages of Combining Blanchard Grinding and Flat Lapping

Combining both methods in the manufacturing process offers several key advantages:

- Optimized Surface Finish: Blanchard grinding efficiently removes material to prepare the part for finishing, while flat lapping refines the surface to achieve unparalleled flatness and smoothness.

- Dimensional Accuracy: The combination can correct out-of-flatness and other geometric imperfections effectively. Blanchard grinding addresses material removal needs, while flat lapping ensures precise dimensional control.

- Improved Efficiency: By leveraging the strengths of both processes, manufacturers streamline operations, reduce handling times, and minimize scrap. This results in enhanced production efficiency and cost-effectiveness.

- High-Quality Parts: The synergistic approach results in parts with superior surface finishes, dimensional accuracy, and minimal scrap, meeting stringent quality standards across industries.

Choosing the Right Method for Your Needs

When deciding whether to integrate Blanchard grinding, flat lapping, or both, consider:

- Part Geometry and Material: Assess the complexity of part geometries and material characteristics to determine which process or combination best meets your requirements.

- Surface Finish Standards: Evaluate the required surface finish specifications, including flatness and smoothness, to select the most appropriate machining method.

- Production Volume and Efficiency: Balance between material removal rates and precision requirements to optimize production throughput and operational efficiency.

Conclusion: Blanchard Grinding and Flat Lapping

Combining both methods harnesses complementary strengths to achieve exceptional surface finishes, dimensional accuracy, and operational efficiencies in precision machining. Manufacturers can benefit from reduced lead times, minimized scrap, and enhanced part quality by strategically integrating these processes. Explore how Grind Lap can elevate your manufacturing capabilities with our integrated precision machining solutions.

Recent Comments