Are you finding it challenging to choose the right honing stone for your cylindrical honing projects? The wrong choice can impact the surface finish and accuracy of your work, leading to less-than-ideal results and inefficiencies. Learn about the importance of selecting the ideal honing stone.

At Grind Lap, we specialize in honing technology and understand the critical factors in selecting the right honing stone. Our expertise can help you navigate the selection process, ensuring you achieve the best results for your specific application.

This article provides a comprehensive guide on how to choose the ideal stone for your cylindrical honing needs. We’ll cover key considerations, including material identification, surface finish requirements, and more, to help you make informed decisions and enhance your honing projects.

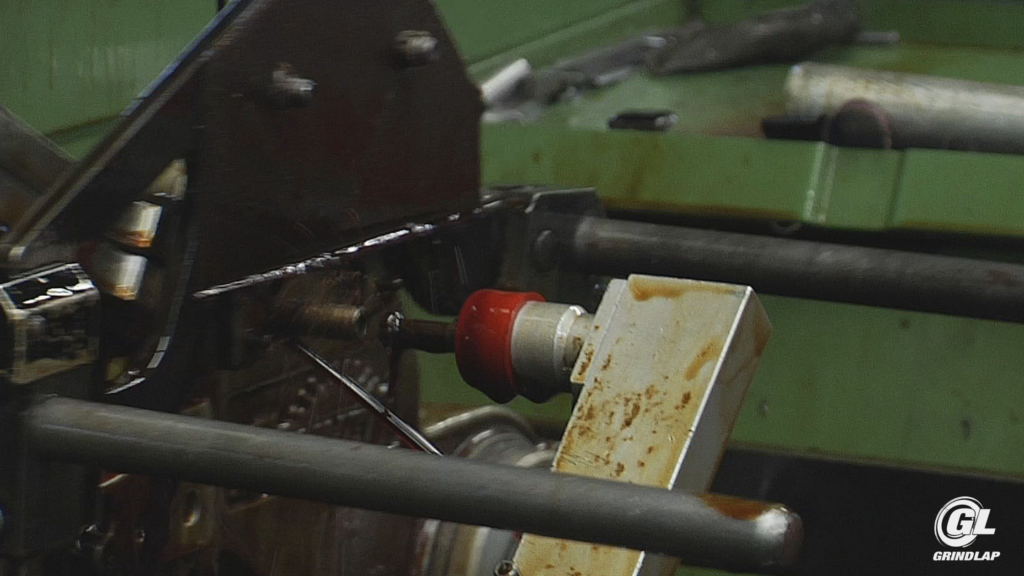

Choosing the Right Stone for Your Cylindrical Honing Project

Selecting the right stone is essential for achieving the desired surface finish and geometry in cylindrical honing. Here’s a step-by-step guide to help you make the best choice:

1. Identify the Material of the Workpiece

- Material Type: Determine the material of the workpiece to select the appropriate abrasive material and grit size. For example, honing steel requires different abrasives compared to ceramics or carbide.

2. Determine the Required Surface Finish

- Finish Requirements: Assess the desired surface finish based on the workpiece’s intended use. Higher finishes are needed for parts like piston cylinders compared to hydraulic cylinders.

3. Determine the Required Geometry

- Shape and Size: The bore’s shape and size will influence the size and shape of the honing stone. Ensure the stone matches the geometry of the workpiece for effective honing.

4. Choose the Appropriate Abrasive Material

- Aluminum Oxide: Versatile and suitable for honing a variety of materials, including steels and stainless steel.

- Silicon Carbide: More aggressive, ideal for harder materials like ceramics and carbide.

5. Choose the Appropriate Grit Size

- Grit Size: Finer grits produce a smoother finish but remove material more slowly. Coarser grits remove material faster but may leave a rougher surface.

6. Choose the Appropriate Shape and Size

- Shape and Size: The honing stone should be slightly larger than the bore to ensure complete contact with the walls. Select a stone that matches the bore’s dimensions.

Conclusion

Choosing the right honing stone involves evaluating the workpiece material, surface finish needs, geometry, abrasive type, grit size, and stone dimensions. By carefully considering these factors, you can ensure optimal performance and results in your cylindrical honing projects. Follow these guidelines to achieve precise, high-quality finishes and improve the efficiency of your honing process.

Recent Comments