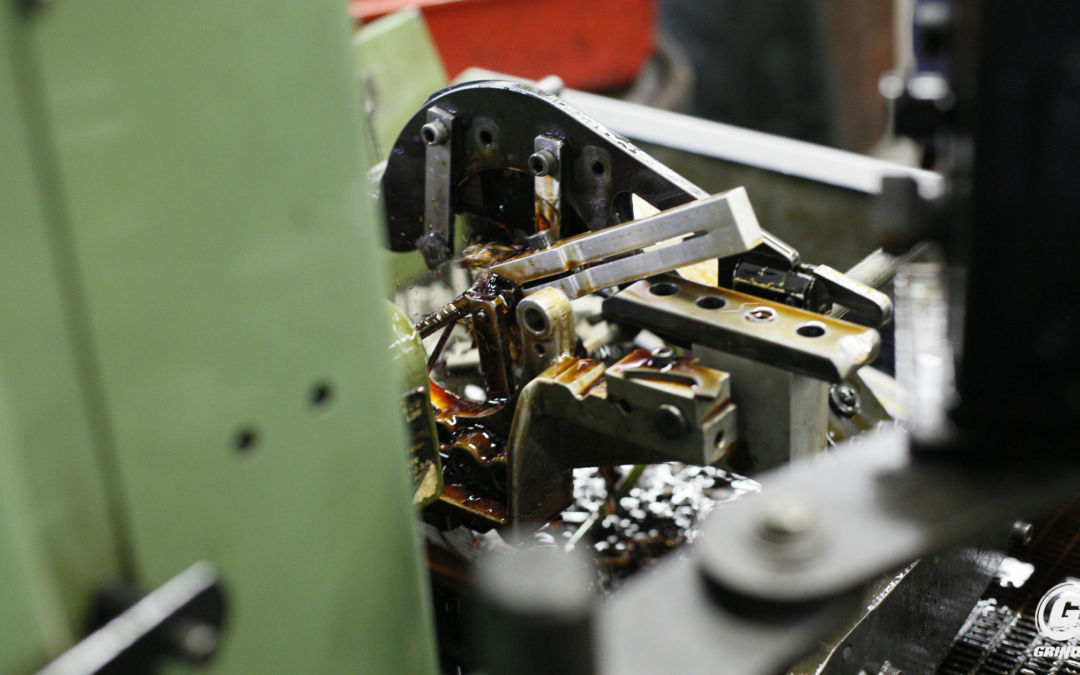

Is your Sunnen hone experiencing slowdowns or inconsistent results? Frequent issues with oil flow or machine performance might be linked to an overlooked yet crucial maintenance task: changing the filter. Neglecting this simple step can lead to a host of problems that affect both the efficiency and lifespan of your equipment.

At Grind Lap, we understand the importance of maintaining precision equipment like the Sunnen hone. Our expertise in honing technology and machine upkeep allows us to offer detailed guidance on maintaining optimal performance. We’ll explain why regular filter changes are key to your machine’s success and how they can enhance your overall honing process.

This article will explore the critical reasons to change the filter in your Sunnen hone regularly. In addition, you’ll learn about how filter maintenance impacts contamination control, oil flow, machine longevity, and finish quality. With these insights, you’ll be equipped to ensure your hone operates smoothly and delivers the best possible results.

The Importance of Regular Filter Changes in a Sunnen Hone

Maintaining a Sunnen hone involves more than just routine checks. Changing the filter regularly is essential for ensuring the machine runs smoothly and efficiently. Here’s why:

1. Prevents Contamination

- Debris and Particles: During honing, debris and particles can contaminate the honing oil. A clogged filter fails to trap these contaminants, which can then circulate through the machine, causing damage to honing stones, cylinders, and other components.

- Efficient Operation: Regularly changing the filter helps prevent contamination, ensuring the machine operates efficiently and prolongs the life of its components.

2. Improves Oil Flow

- Clogged Filter Issues: As the filter becomes clogged with debris, oil flow can be restricted. This restriction may slow down or even halt the honing process.

- Consistent Performance: Regular filter changes maintain consistent oil flow, preventing disruptions in the honing process and maintaining smooth operation.

3. Extends Machine Life

- Wear and Tear: A clogged filter can lead to unnecessary wear on the machine’s components. This increases maintenance costs and potentially shortening the machine’s lifespan.

- Cost-Effective Maintenance: By changing the filter regularly, you reduce wear and tear, helping to extend the life of your Sunnen hone and avoid costly repairs.

4. Enhances Finish Quality

- Impact of Contamination: Contaminated honing oil can negatively affect the finish quality of honed parts, leading to subpar results.

- Higher Quality Finish: Regular filter changes keep the honing oil clean and free of contaminants, resulting in a higher quality finish on honed parts.

Conclusion for Optimal Sunnen Hone Performance

Regularly changing the filter in your Sunnen hone is a key maintenance practice that ensures smooth and efficient machine operation. It helps prevent contamination, maintains consistent oil flow, extends the life of your equipment, and enhances finish quality. For optimal performance, it is recommended to consult your users manual to determine the suggested time frame to change the filter or sooner if needed. In conclusion, by adhering to these guidelines, you can maximize the effectiveness and longevity of your Sunnen hone, ensuring reliable and high-quality honing results.

Recent Comments