Is your lapping process yielding inconsistent results? Uneven lapping surfaces and increased scrap rates can be frustrating and costly. If you’re facing challenges with maintaining the flatness of your lapping table, it’s time to address this issue to enhance your machining accuracy by conditioning your lapping table.

At Grind Lap, we specialize in precision lapping and conditioning processes. With extensive experience and a deep understanding of lapping technologies, we guide manufacturers in optimizing their lapping tables for superior performance. Our insights help ensure that your lapping operations are both efficient and precise.

In this article, you’ll discover the importance of conditioning your lapping table, step-by-step conditioning procedures, and how regular maintenance can improve your lapping results. By the end of this guide, you’ll be equipped to maintain the flatness of your lapping table and achieve high-quality, consistent results in your machining processes.

Conditioning Your Lapping Table

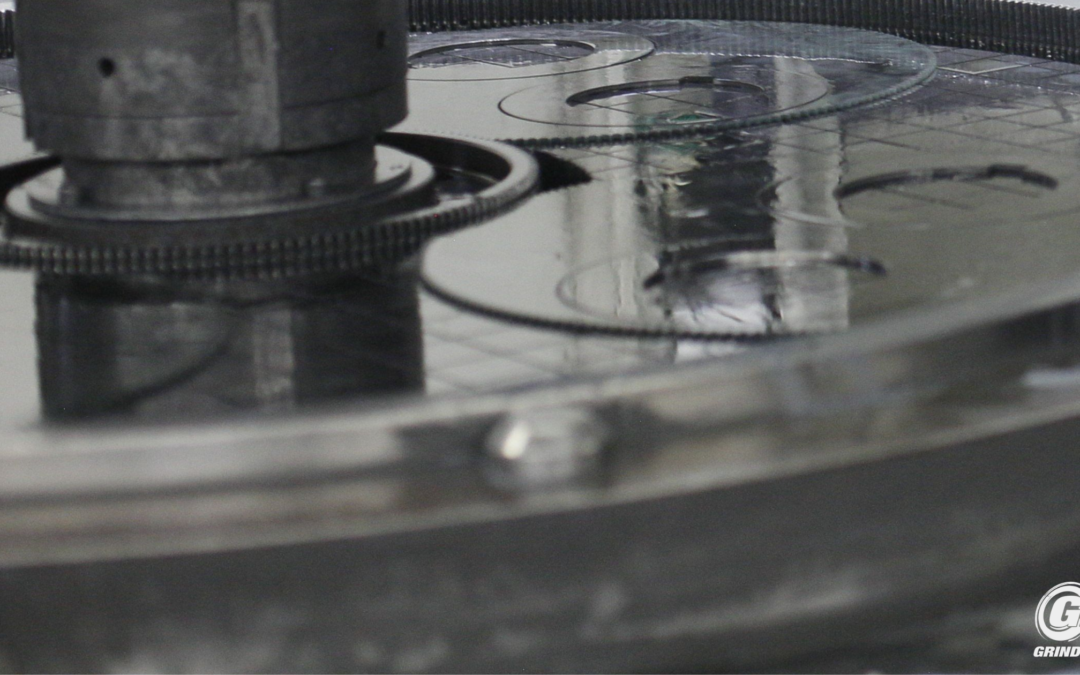

Lapping is a precision machining process that involves rubbing two surfaces together using abrasive particles to achieve a precise fit. A lapping table, which serves as a flat surface for this process, must be regularly conditioned to maintain its flatness and ensure accurate results.

Why Conditioning is Important

Over time, a lapping table can become uneven due to wear and tear, scratches, and other imperfections. These issues can lead to inaccuracies in the lapping process, resulting in poor-quality parts and increased scrap rates. Conditioning the lapping table is crucial for maintaining its flatness and ensuring that the lapping process yields precise and consistent results.

Steps to Condition a Lapping Table

- Cleaning the Table:

- Begin by thoroughly cleaning the lapping table to remove any debris or contaminants that might interfere with the lapping process.

- Setting Up the Conditioning Rings:

- Place conditioning rings on the table. These rings will be used to distribute the abrasive slurry across the lapping surface.

- Preparing the Abrasive Slurry:

- Add abrasive to the slurry. The slurry typically consists of abrasive particles suspended in a liquid, such as water or oil.

- Conditioning Process:

- Rotate the lapping plate at a slow speed while evenly spreading the abrasive slurry across the table. This step involves rubbing the abrasive particles against the lapping plate, which helps remove any high spots and creates a flat, uniform surface.

- Final Cleaning and Inspection:

- Once the conditioning is complete, thoroughly clean the lapping plate to remove any residual slurry or debris. Inspect the plate to ensure it is flat and uniform, addressing any remaining imperfections with additional conditioning if necessary.

Benefits of Proper Conditioning

- Accuracy: Ensures a flat and consistent lapping surface, leading to precise machining results.

- Quality: Reduces scrap rates and improves the quality of finished parts.

- Efficiency: Maintains optimal performance of the lapping table, enhancing overall manufacturing efficiency.

Conclusion

Conditioning your lapping table is essential for maintaining accuracy and consistency in your lapping process. By following proper conditioning procedures, you can ensure that your table remains flat and effective, leading to high-quality parts and minimal scrap. For more expert advice on lapping and other precision machining processes, visit our Grind Lap services page.

Recent Comments